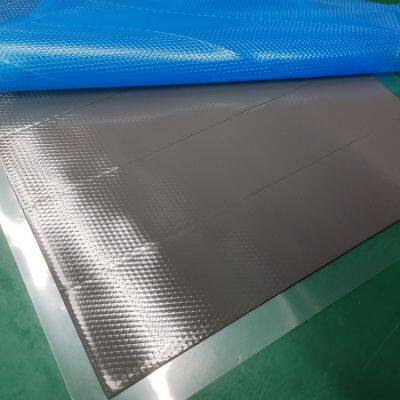

BERGQUIST GAP PAD Thermally Conductive

The BERGQUIST brand is a world leader in thermal interface materials. The GAP PAD family of products was developed

to meet the electronic industry’s growing need for interface materials with greater conformability, higher thermal

performance and easier application.

Features

Each of the many products within the BERGQUIST GAP PAD family is unique in its construction, properties and performance.

Following is an overview of the important features offered by the BERGQUIST GAP PAD family.

• Low-modulus polymer material

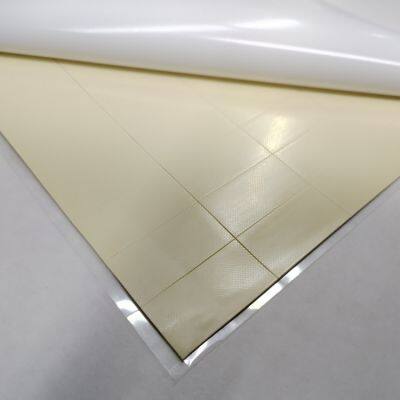

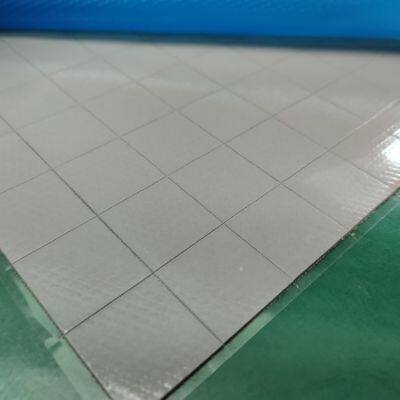

• Available with fiberglass/ rubber carriers or in a non-reinforced version

• Special fillers to achieve specific thermal and conformability characteristics

• Highly conformable to uneven and rough surfaces

• Electrically isolating

• Natural tack on one or both sides with protective liner

• Variety of thicknesses and hardnesses

• Range of thermal conductivities

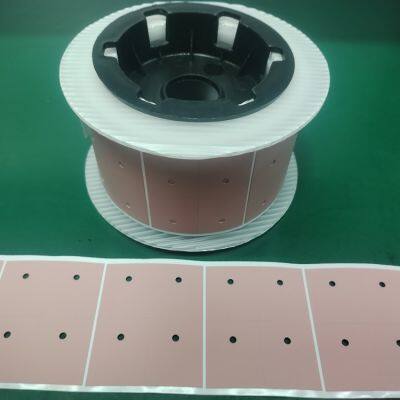

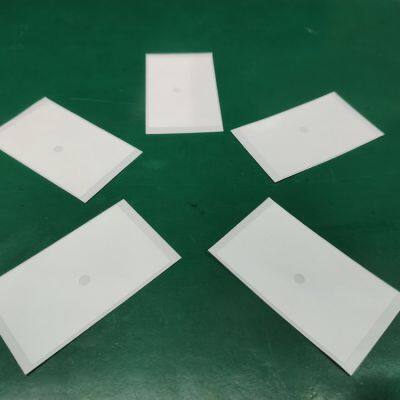

• Available in sheets and die-cut parts

Q: Is GAP PAD offered with an adhesive?

A: Currently, BERGQUIST GAP PAD TGP 800VO(BERGQUIST GPVO、GAP PAD VO),

BERGQUIST GAP PAD TGP 800VOS(BERGQUIST GPVOS、GAP PAD VO Soft),

and BERGQUIST GAP PAD TGP 1000VOUS(BERGQUIST GPVOUS、GAP PAD VO Ultra Soft)

are offered with or without an adhesive and on the carrier-side of BERGQUIST SIL PAD TSP 1600(BERGQUIST SP900S、SIL PAD 900S) and

BERGQUIST SIL PAD TSP 900. The remaining surface has natural inherent tack. All other GAP PAD materials have inherent tack.

Q: Can GAP PAD with natural tack be repositioned?

A: Depending on the material that the pad is applied to, in most cases they are repositionable. Care should be taken

when removing the pad from aluminum or anodized surfaces to avoid tearing or delaminating the pad. The

side with the natural tack is always easier to reposition than an adhesive side.

Q: Is GAP PAD reworkable?

A: Depending on the application and the pad being used, GAP PAD has been reworked in the past. Some of our

customers are currently using the same pad for reassembling their applications after burn-in processes and after fieldwork

repairs. However, this is left up to the design engineer’s judgment as to whether or not the GAP PAD will withstand reuse.

Recently Posted

-

Performance Champion - The Best Thermal Conductive Insulating sheet

November 28, 2023The lower the hardness of the thermally conductive silicone sheet means the higher the softness of the product, so Read More

Read More -

15W/m.k Super Thermal pad outperforms BERGQUIST SP2000

November 13, 2023HOTHREE HSR-8000 is a special production process to prepare a new product of ultra-high thermal conductivity, the product is Read More

Read More -

15W/m.k Super Thermal pad outperforms BERGQUIST SP2000

November 13, 2023HOTHREE HSR-8000 is a special production process to prepare a new product of ultra-high thermal conductivity, the product is soft, tough, with ultra-high thermal conductivity, while at the same time a certain degree of insulation properties, performance far beyond the world's first-tier brands of similar products.1. Thermal conductivity and thermal resistance of materials. As we all know, thermal conductivity isRead More -

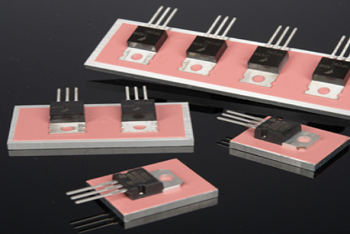

Thermally conductive bonding film to replace locking screws

October 23, 2023Thermally conductive heat curable laminate material is used to fix and thermally conductive adhesive bonding between MOS tube Read More

Read More