What is the Phase change materials(PCM)

Phase change materials (PCM)are used for storing latent heat during the phase transition enabling the

temporary storage of low or high-temperature energy for later use.

This latent heat transition can be achieved with solid-solid, solid-liquid, solid-gas, and liquid-gas phase change.

However, at the commercial level, only solid-liquid phase change is used in advanced PCMs since other methods require a large volume and high pressure.

Phase change materials (PCM) store and release large amounts of heat as they transition between solid and liquid states.

The process of absorbing heat causes the material to change from a solid to a liquid, and it changes back from a liquid to a solid once the energy stored is released.

This allows PCM to act as a heat dissipation medium, and they are used in a variety of applications to improve thermal management.

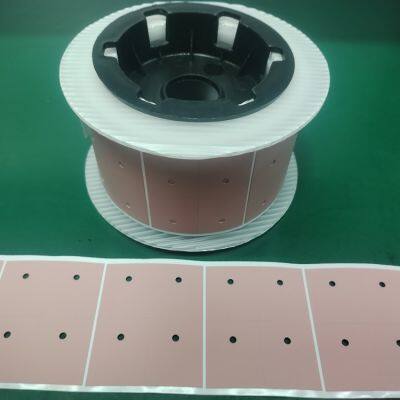

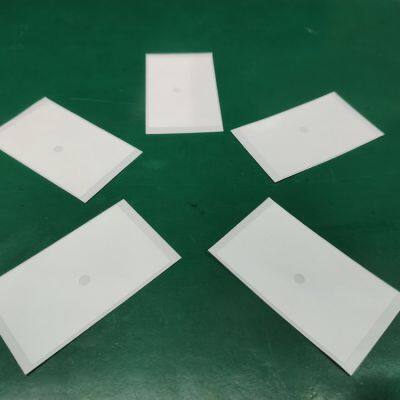

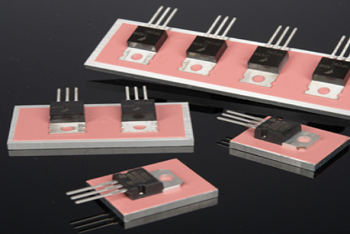

BERGQUIST HI-FLOW phase change materials are an excellent replacement for grease as a thermal interface between a CPU or power device and a heat sink.

The materials change from a solid at specific phase change temperatures and flow to assure a total wet-out of the interface without overflow.

The result is a thermal interface comparable to grease, without the mess, contamination and hassle.

A key advantage of phase change materials(PCM) is their high energy density, which allows them to store a large amount of heat energy in a relatively small volume.

This makes them well suited for applications where space is limited, such as in electronic devices.

Another benefit of PCM is that they can maintain a relatively constant temperature over a long period of time,

which makes them well suited for applications where temperature stability is important.

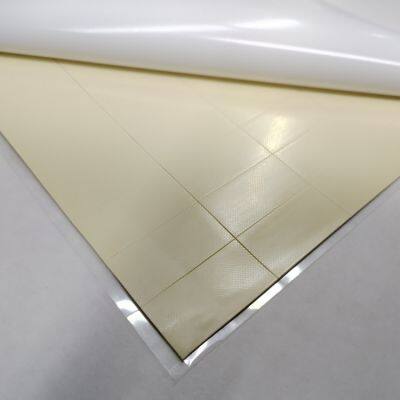

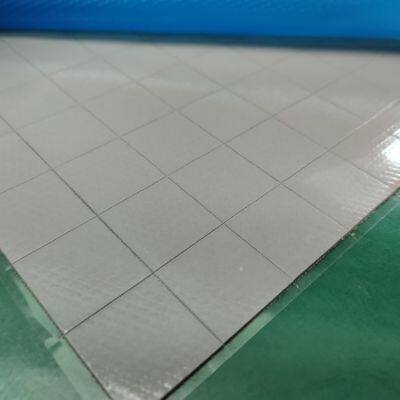

Phase change materials can be used in a variety of ways to improve thermal management.

For example, they can be used in electronic devices to dissipate heat and keep components from overheating,

they can also be used in industrial processes, to keep machinery running at optimal temperature levels.

Commonly used phase change materials are BERGQUIST HI-FLOW THF 1600P, HI-FLOW 300P,HI-FLOW THF 700UT,HI-FLOW 225-UT,

HI-FLOW THF 3000UT,HI-FLOW 565UT,HI-FLOW THF 1500P, HI-FLOW 650P,Honeywell PCM45F,PCM45F-SP

Recently Posted

-

Performance Champion - The Best Thermal Conductive Insulating sheet

November 28, 2023The lower the hardness of the thermally conductive silicone sheet means the higher the softness of the product, so Read More

Read More -

15W/m.k Super Thermal pad outperforms BERGQUIST SP2000

November 13, 2023HOTHREE HSR-8000 is a special production process to prepare a new product of ultra-high thermal conductivity, the product is Read More

Read More -

15W/m.k Super Thermal pad outperforms BERGQUIST SP2000

November 13, 2023HOTHREE HSR-8000 is a special production process to prepare a new product of ultra-high thermal conductivity, the product is soft, tough, with ultra-high thermal conductivity, while at the same time a certain degree of insulation properties, performance far beyond the world's first-tier brands of similar products.1. Thermal conductivity and thermal resistance of materials. As we all know, thermal conductivity isRead More -

Thermally conductive bonding film to replace locking screws

October 23, 2023Thermally conductive heat curable laminate material is used to fix and thermally conductive adhesive bonding between MOS tube Read More

Read More