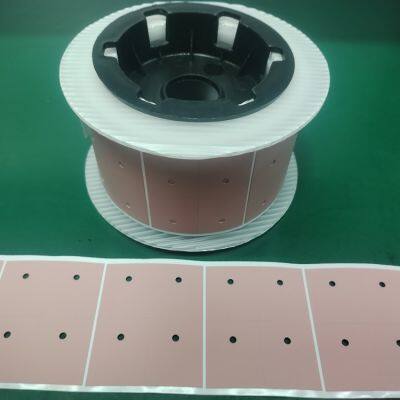

Thermal pad - Die-cutting process

Thermal pad - Die-cutting process

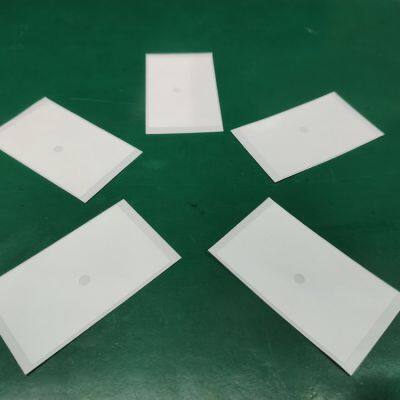

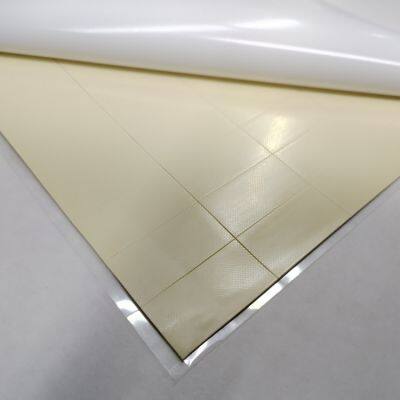

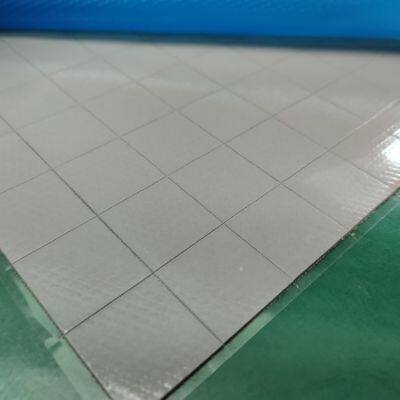

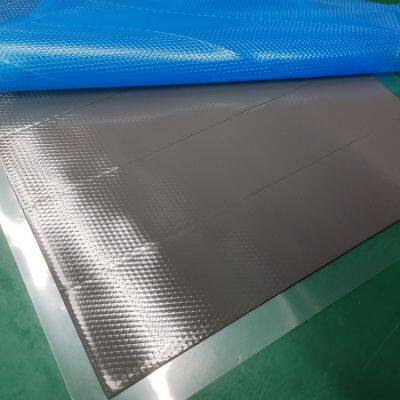

Thermal pads are usually cut from sheet material to suit the customer's requirements. Depending on the manufacturer of the thermal interface material, the standard sheet size is usually less than 24" x 24".

Many material processors will use a die-cutting process to create a thermal pad to meet the customer's specific requirements. While there are several methods of cutting thermal mats, the die-cutting or stamping method consistently produces excellent quality parts that meet the tightest tolerance specifications, especially on thinner materials.

A die is required for the manufacture of heat-conductive mats using this cutting method. The die can be used to make tens of thousands of parts, or in some cases hundreds of thousands of parts, before they need to be replaced. The good thing is that the mould can be used to make tens of thousands of parts, or in some cases hundreds of thousands of parts, before they need to be replaced.

Thermal pad - the advantages

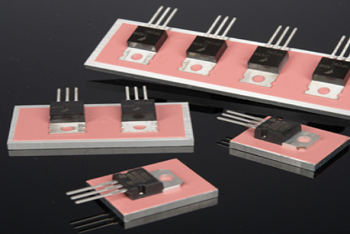

The biggest advantage of using a thermal pad is its portability. Die-cut thermal pads can be shipped anywhere in the world and used in multiple locations on the factory floor without the need to program robots or train technicians. The pads are cut in advance and used on demand.

The pads can continue to be carried after they have been installed in place. It is perfectly possible to mount the pads on the heat sink on day one and then ship these pads to the assembly plant two days later to be mounted on the PCB.

Another major advantage of using die-cut thermal pads is that there is a wide range of materials available to overcome the challenges of thermal management.

Probably the biggest disadvantage of using thermal pad is that they can be more expensive than thermally conductive fillers. As mentioned earlier, thermal pads are cut from sheets. Depending on the size of the pad and sheet, you can usually expect a maximum sheet utilisation of 90%.

Commonly used thermal pad models are FUJIPOLY PG80A,FUJIPOLY PG80B,LAIRD TFLEX 300,LAIRD TFLEX 600,FUJIPOLY GR-HM,BERGQUIST thermal pad,DENKA FSL-BS

Recently Posted

-

Performance Champion - The Best Thermal Conductive Insulating sheet

November 28, 2023The lower the hardness of the thermally conductive silicone sheet means the higher the softness of the product, so Read More

Read More -

15W/m.k Super Thermal pad outperforms BERGQUIST SP2000

November 13, 2023HOTHREE HSR-8000 is a special production process to prepare a new product of ultra-high thermal conductivity, the product is Read More

Read More -

15W/m.k Super Thermal pad outperforms BERGQUIST SP2000

November 13, 2023HOTHREE HSR-8000 is a special production process to prepare a new product of ultra-high thermal conductivity, the product is soft, tough, with ultra-high thermal conductivity, while at the same time a certain degree of insulation properties, performance far beyond the world's first-tier brands of similar products.1. Thermal conductivity and thermal resistance of materials. As we all know, thermal conductivity isRead More -

Thermally conductive bonding film to replace locking screws

October 23, 2023Thermally conductive heat curable laminate material is used to fix and thermally conductive adhesive bonding between MOS tube Read More

Read More